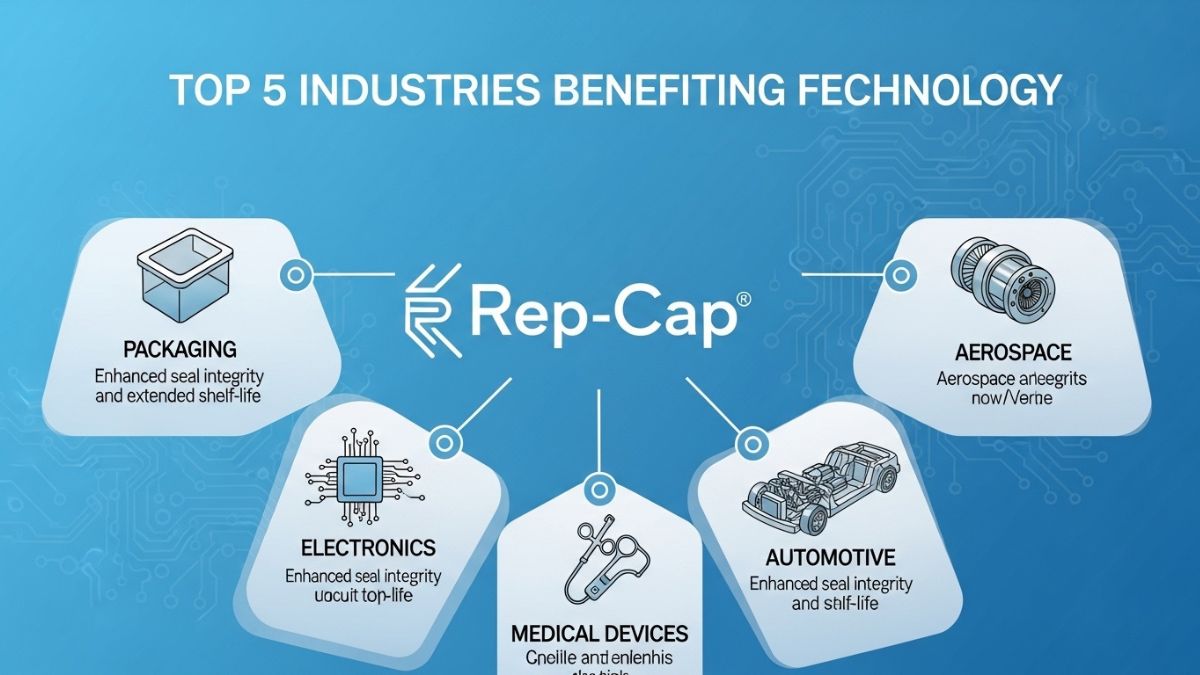

In today’s rapidly evolving landscape, innovation is key to staying competitive. One technology that is making waves across multiple sectors is repmold. This groundbreaking method combines efficiency and precision like never before, transforming the way products are created and produced. As industries harness its power, they are discovering new pathways for growth and optimization.

From healthcare innovations to advancements in aerospace manufacturing, repmold technology has become a game-changer. It offers solutions that not only enhance product quality but also streamline production processes. Let’s explore how this revolutionary technology is reshaping five major industries, driving them into an exciting future filled with possibilities.

Advancements in repmold technology and its impact on industries

Repmold technology has seen remarkable advancements, changing the landscape of various industries. Innovations in materials and processes have made it possible to create complex designs with precision and efficiency.

The introduction of advanced polymers has enhanced durability while maintaining lightweight properties. This is crucial for applications where strength-to-weight ratios are essential.

Automation plays a significant role as well. Smart manufacturing techniques streamline production lines, reducing lead times significantly. With these improvements, businesses can adapt quickly to market demands without sacrificing quality.

Sustainability is another key aspect driving change in repmold technology. The shift towards eco-friendly materials not only benefits manufacturers but also appeals to environmentally-conscious consumers.

These advancements collectively empower industries to innovate products that meet diverse needs more effectively than ever before. Adaptation is now synonymous with success across sectors utilizing this cutting-edge technology.

Healthcare industry: Improved medical devices and equipment through repmold technology

Repmold technology is making waves in the healthcare industry, particularly in the production of medical devices. This innovative approach allows for precision molding that enhances device performance and reliability.

With repmold, manufacturers can create complex shapes and designs that were previously difficult or impossible to achieve. This leads to improved functionality in products like surgical instruments and implants.

Customization becomes easier too; healthcare providers can now offer tailored solutions that meet specific patient needs. Such adaptability helps improve treatment outcomes significantly.

Moreover, repmold technology often reduces waste during manufacturing, contributing to more sustainable practices within the sector. The result? Higher quality equipment with lower environmental impact.

As health demands evolve, so does the necessity for advanced technologies like repmold to ensure patients receive optimal care through superior medical devices.

Automotive industry: Faster production process and cost-effectiveness with repmold technology

The automotive industry is experiencing a revolution thanks to repmold technology. This innovative approach streamlines production processes, significantly reducing manufacturing time.

With the ability to create complex shapes and designs in one go, repmold minimizes the need for multiple components. This efficiency not only speeds up assembly but also lowers labor costs. Manufacturers are reaping financial benefits while enhancing productivity.

Moreover, repmold allows for greater precision in parts creation. Higher quality components lead to improved vehicle performance and safety standards.

As car manufacturers strive for sustainability, this technology supports lightweight materials that contribute to fuel efficiency. By adopting repmold methods, companies can achieve both cost savings and environmental responsibility.

Embracing these advancements positions automotive brands at the forefront of innovation in an ever-competitive market.

Consumer goods industry: Customized products through repmold technology

The consumer goods industry has experienced a significant shift thanks to repmold technology. This innovative approach allows for the production of highly customized products tailored to individual preferences.

Imagine purchasing a smartphone case specifically designed to fit your style and needs. With repmold, manufacturers can easily create unique designs in small batches without sacrificing quality or increasing costs.

Customization extends beyond aesthetics. Brands can now integrate features that cater directly to consumer demands, enhancing usability and satisfaction.

This flexibility also means faster turnaround times from concept to market. Companies can respond quickly to changing trends while maintaining a competitive edge.

Shoppers increasingly seek personalized experiences, making customization not just a trend but a vital strategy in the consumer goods landscape. Rep-molding is leading the way in redefining how products are created, ensuring they resonate with today’s discerning buyers.

Aerospace industry: The use of high-performance materials in aircraft manufacturing with repmold technology

The aerospace industry is always pushing the boundaries of innovation. With repmold technology, manufacturers are now able to utilize high-performance materials that significantly enhance aircraft capabilities.

These advanced materials offer superior strength while remaining lightweight. This quality is crucial in aviation, where every ounce counts. By incorporating repmold processes, companies can produce components that withstand extreme conditions without compromising safety or efficiency.

Additionally, the versatility of repmold allows for intricate designs that were previously hard to achieve. Complex geometries become feasible, leading to enhanced aerodynamics and fuel efficiency.

As aircraft design evolves, so does the need for sustainable practices. RepMOLD aligns with this vision by minimizing waste during production. The result? Stronger planes built faster and more sustainably than ever before.

Conclusion:

Repmold technology is reshaping various industries, driving innovation and efficiency. Its impact on healthcare enhances the quality of medical devices, ensuring better patient outcomes. The automotive sector benefits from faster production processes while maintaining cost-effectiveness, translating to more accessible vehicles for consumers.

In consumer goods, repmold allows for a high level of customization that meets diverse consumer needs. Meanwhile, aerospace manufacturers harness this technology to utilize advanced materials that improve aircraft performance and safety.